Case Study

Surface conditioning

Chemical conversion

Degreasing

Concentration Control of Degreasing Solution

It is important to monitor the concentration as it becomes contaminated over time.

*Contact ATAGO for explosion proof models. (CM-ISα)

Rinsing

Concentration Monitoring For Rinse Water

Measures concentration of the rinse water used to wash chemical agents.

Post-treatment coating

(e.g. oil)

Maintaining Proper Concentration

Concentration of surfactant solutions lowers over time. No need to use other analyzers such as HPLC, etc.

Case Study

Surface conditioning

Chemical conversion

Recommended

Products

Introducing US-α

Some types of surfactant are more likely to adhere to the detection section. In such cases, we recommend using the US-α to prevent buildup.

Contact ATAGO for more information.

ATAGO is experienced with surfactants concentration management. For further details, contact ATAGO.

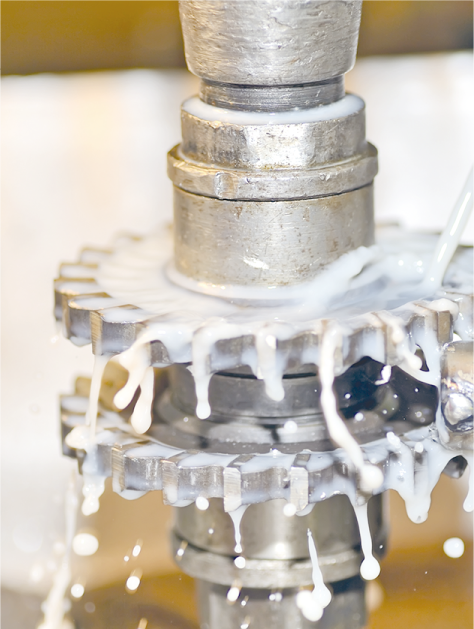

Surface treatment refers to a physical and chemical treatment applied to the surface of solid materials for aesthetic, ornamental, hardening, and enhanced corrosion resistance purposes.

Types of treatments include cleaning, polishing, etching, and coating, but to demonstrate the maximum effectiveness of surface treatment, it must be performed with the same, standard concentration.

Therefore, using in-line refractometers to check whether the concentration is as usual is immensely important.