HACCP is an internationally recognized management method for ensuring safety in the manufacture of food. HACCP is an abbreviation that stands for Hazard Analysis and Critical Control Point, and is translated as "Hazard Analysis and Critical Control Point".

People who are engaged in food-related businesses investigate and understand problems (harmful factors) such as contamination by foreign substances and food poisoning bacteria based on the hygiene management plan, and all processes (from raw material arrival to manufacturing, products). It is for hygiene management (until shipment) and to improve the safety of products and foods.

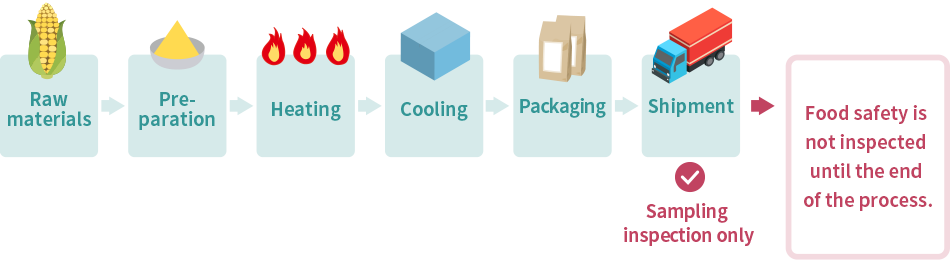

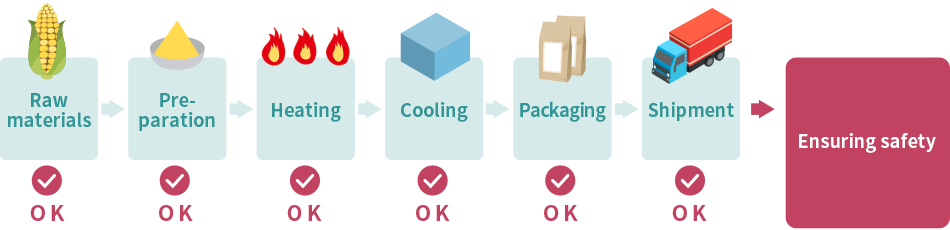

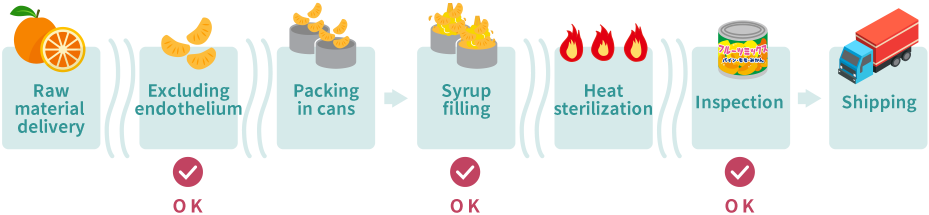

Until now, sampling inspection of final products has been the mainstream, but the hygiene control method using the HACCP system is linked to preventing food accidents by checking for hazards in each process and performing continuous hygiene control. Our instruments can help ensure the quality and safety of your products.

With the globalization of food manufacturing and distribution, improving food safety has become a common issue in countries and regions around the world.

In 1993, the Codex Alimentarius Commission, which sets international standards for food, set guidelines for hygiene control by HACCP, and the trend toward mandatory hygiene management is progressing mainly in developed countries. Therefore, it is now an international standard, such as the requirement for hygiene control by HACCP for foods exported from Japan.

In Japan as well, based on the revision of the Food Sanitation Law, the HACCP system was enforced from June 1, 2020. Full enforcement is June 1, 2021. Under the revised Food Sanitation Law, in principle, all businesses are required to have "hygiene management in line with HACCP", so let's prepare to respond by June 1, 2021.

The introduction of HACCP is premised on the hygienic maintenance and management of the manufacturing environment such as equipment and employees. By implementing hygiene management by HACCP in addition to daily hygiene management, it is possible to prevent food contamination and foreign matter contamination and provide safe and hygienic food.

When proceeding with the introduction of HACCP, a hazard analysis is performed according to the 12 procedures listed in the Codex Alimentarius Committee's "Guidelines for HACCP System and Its Application", and the critical control points (CCP) are determined based on the results. Then create a HACCP plan.

With this plan, the HACCP system is a hygiene control method that prevents the final product from leaving any hazards that could damage health. The 12 procedures consist of the pre-stage for hazard analysis, which consists of 5 steps from the formation of the HACCP team to promote the work to the confirmation of the site, and the "7 principles" from the hazard analysis to the record.

In food safety science, what can cause health hazards to humans through food if not properly managed is called a hazard factor. Hazard factors are divided into three categories: "biological", "chemical", and "physical". When analyzing hazards in HACCP, it is necessary to consider the hazards using these three classifications.

Many biological hazards refer to potential health hazards caused by microorganisms.

It can be roughly divided into (1) bacteria, (2) rickettsia, (3) virus, (4) protozoan, (5) yeast, and (6) mold. The damage caused by these is mainly food poisoning, and in some cases, the damage can be serious.

Chemical hazard refers to the danger of "chemical substances" such as chemicals, cleaning agents, and pesticides being accidentally mixed into food and causing harm to consumers.

The amount of additives such as sodium nitrite used in the production of sausages and hams and the amount of residuals are determined by the "Standards for Foods, Additives, etc." If you do, safety cannot be guaranteed and it can be a chemical hazard.

Physical hazards include health hazards from hard foreign substances that are not normally contained in food.

Foreign substances such as metal pieces and glass pieces that may damage the mouth and digestive tract. In addition to being brought in when the ingredients are delivered, it may occur due to damage to kitchen knives, mixers, and other kitchen equipment used in the manufacturing process.

When distributed at room temperature, some bacteria may remain in the case of sterilization that does not meet the retort conditions (60 minutes boil sterilization, etc.). Therefore, in order to inactivate this, it is necessary to confirm that the water activity is 0.94 or less by replacing it with the Brix value (sugar content) or more.

Brix and acidity are measured during the training / guidance of certified agricultural personnel by extension instructors.

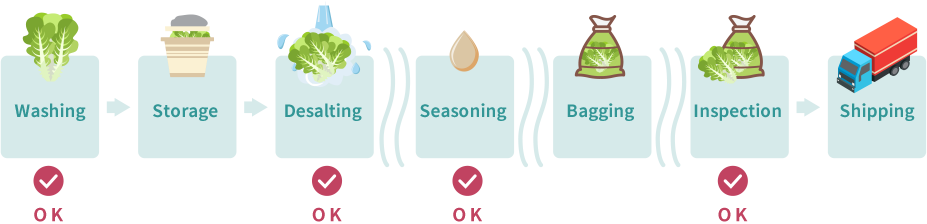

After receiving vegetables ① Cleaning ② Large cut ③ Cleaning ④ Fine cutting ⑤ Sterilization cleaning ⑥ Draining ⑦ Packaging ⑧ There is a shipping process.

The cleaning solution is electrolyzed water / hypochlorous acid water: pH 2.5-3.5 for non-heated foods, soaked in sodium hypochlorite: 100-200 ppm for 5-10 minutes for boiled products.

You can manage the water used for washing by measuring its specific gravity. A lower specific gravity would indicate a cleaner water, a higher specific gravity would indicate a dirtier water. A higher specific gravity might also indicate that the fish needs more washing.

A Brix meter is used to formulate the seasoning liquid. In some cases, a seasoning liquid (injection liquid) that is used repeatedly and has a sweet taste, is added, and quantification is essential to maintain the quality of the taste.

Used to control the concentration of saline solution mixed with Jiuqu (in-line is also possible). A hydrometer can also be used.

The mandarin orange bag (inner pericarp) is dissolved using hydrochloric acid and caustic soda (sodium hydroxide). Use extremely thin hydrochloric acid (0.5%), soak it in caustic soda (0.2%) as a neutralizer, wash it with water, and expose it to water so that it does not remain. After processing, the pH of the flesh is inspected to make sure that it does not remain in the flesh.

Electrolyzed water / hypochlorous acid water or sodium hypochlorite * pH meter Desalting

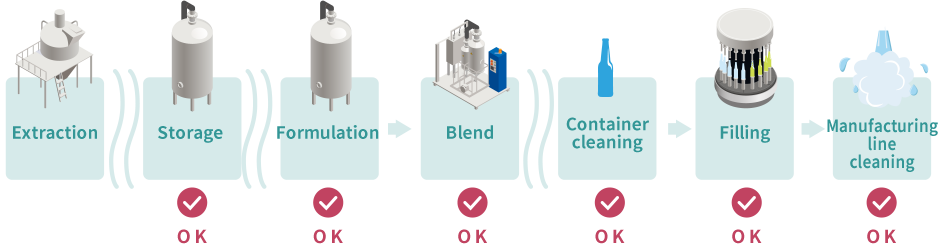

By knowing the Brix of the extracted liquid, the extraction rate is managed. Depending on the extraction rate, re-extraction may be performed.

Check if there is any problem with the liquid by measuring the concentration of the liquid before blending.

The mixing ratio can be detected in real time, and feedback is given to prevent non-standard products.

Container cleaning (caustic soda, phosphoric acid) → wastewater (biological) treatment layer

A final check is made to see if the product before filling is within the standard. It can also be used to reduce liquid loss by managing the switching to water during cleaning.

・After production is completed, CIP / SIP cleaning of the production line (caustic soda, phosphoric acid, sugar, organic acid) → to wastewater (biological) treatment layer: High-concentration wastewater (Brix 1% or more) and low-concentration wastewater (Brix 0.2%) Brix measurement (PRM / CM) for classification management of (below), pH measurement after neutralization treatment of CIP washing wastewater

・Brix measurement after confirming the completion of wastewater treatment (Brix 0%)