In-line Refractometer

The PRM series measures the Refractive Index, Brix, concentration/water content, mixing ratio, etc. of various solutions with high accuracy. In particular, the PRM-2000α can measure low-sugar beverages, cleaning solutions, wastewater, etc. that are below 2.000% Brix with a high accuracy of ± 0.007%.

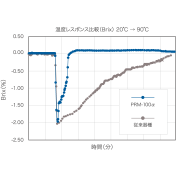

The PRM series is equipped with automatic temperature compensation (ATC) and supports a wide range of temperatures from 5℃ to 100℃ (PRM-2000α is 5 to 90℃). Since the wetted surface can handle up to 160℃, use CIP and SIP cleaning with confidence!

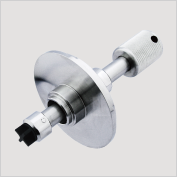

By making the sample stage (wetted part) completely flat, the adhesion of the sample liquid to the prism surface is minimized and is more hygienic. The prism stage is re-polished in 1/100 mm increments during manufacturing to eliminate the chance of slight uneveness that may occur between the prism surface and the prism stage.

Due to their nature, some sample liquids will adhere or build up on the prism no matter what after longterm use. For these cases, ATAGO has designed both prism wiper and ultrasonic cleaning devices. Using either of these means is no need to stop the line or remove the in-line refractometer many times just to clean the prism when buildup occurs.

For use with harsh chemicals, the wetted part of the PRM series can be customized. The PRM series is standard stainless steel but can be changed to Hastelloy or titanium by request. Because all the metal is shaved and polished in-house, we can flexibly respond to changes in materials.

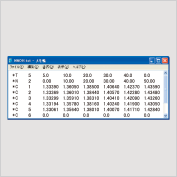

In addition to Brix and refractive index, the PRM series has an additional special scale feature that will display the concentration % of a specific sample.Customers can customize their PRM inline refractometer's special scale by preparing and entering the sample's "refractive index vs. concentration (all temperatures)" data.If data is provided beforehand, we can also input the data for the customer instead.

Customers must stop production if there is an issue with the system or inline refractometer, which can cause a big impact.For that reason, reliability and a good track record are important points.The PRM series is a long-selling product that has been highly acclaimed around the world for 38 years.ATAGO provides excellent support and aftercare service from offices and service center around the world should you encounter any issue.

The PRM series is equipped with a function that outputs an alarm signal when a value that exceeds the set control range is detected.This is a very convenient function to quickly detect nonconformities in the production line.Using relay drive, it is possible to detect and control the occurrence of abnormal values by lighting the alarm lamp, inputting to the sequencer, etc.Moreover, as a data output function, the recorder output (DC4mA ~ 20mA) and RS-232C output are an option.

ATAGO's inline refractometer meets the safety and health standard institutions EHEDG and 3-A Sanitary Standards requirement for instrumentation's wetted parts surface finish to be Ra 0.8 or less, clearing EC No 1935/2004 as well as FDA (21 CFR)-GRAS(Generally Recognized as Safe). These specifications clear the component requirements for stainless steel so the inline refractometer can be used with confidence.

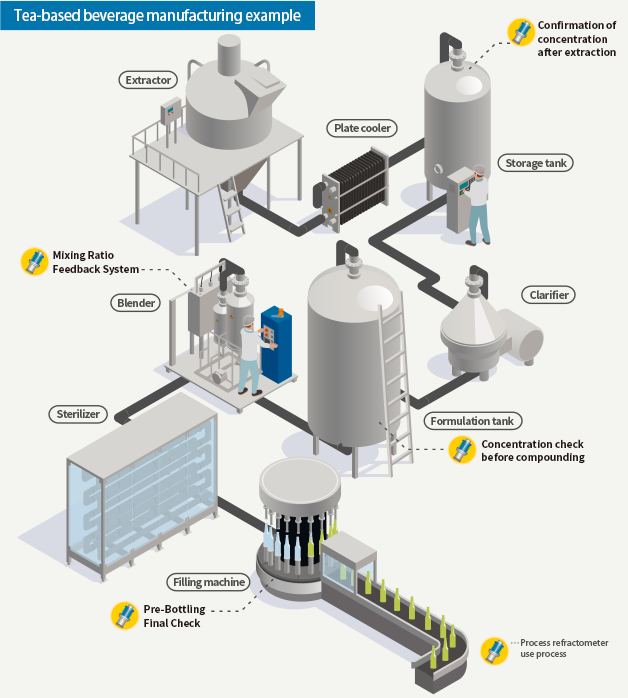

Block nonconformities by process

Check the concentration of the extract

Manage extraction yield by measuring the Brix of the extracted solution.Depending on the extraction rate, re-extraction may be performed.

Mixing Ratio Feedback System

The mixing ratio can be detected in real time, and feedback is given so that there are no non-standard products.

Pre-Bottling Final Check

A final check on the product before bottling is made to make sure it is within specifcations.It can also be used to reduce liquid loss by controlling the switching to water during cleaning.

For details, please contact ATAGO.

SUS(standard specification)

Stainless steel with high strength and excellent corrosion resistance.Sanitary specification.

Titanium

Metal with high strength, light weight, corrosion resistance, heat resistance. In particular, it has higher corrosion resistance to salt than the stainless steel.

Hastelloy

Alloy with high corrosion resistance and heat resistance. Alloy with high corrosion resistance and heat resistance. * Hastelloy is a trademark of Haines Corporation, USA.

For details, please contact ATAGO.

What is VARIVENT®?

VARIVENT® is a standard for pipeline installation. Mainly used in Europe, but also in countries around the world. The wetted parts of In-line Refractometers may be customized to work with VARIVENT® components. PRM series and CM series fittings that meet VARIVENT standards are also available.

* VARIVENT® is a registered trademark of GEA Tuchenhagen.

Pipeline Fitting Sizes

Correct Installation Methods

Choose Pipeline Fitting Type and Size