Frying Oil Monitor

| JP: | PAT#6435565 PAT#6395243 PAT#6471300 | ||

| TW: | PAT# I574004 | KR: | PAT# 10-1975308 |

| NC: | ZL 2019 9 0000638.1 | ||

― Is your oil still fresh? ―

Once oil degrades, it must be replaced with new, fresh oil. Continued use of old, degraded oil can have many negative consequences. Not only does it spoil the quality and flavor of food, it may also gravely impact the health of your customers. By managing the quality and condition of degraded oil using quantitative, objective values, you can determine just the right time to change out the oil. It can also be extremely useful in reducing costs and improving the quality and flavor of your food products.

As oil degrades, harmful peroxides are produced from the unsaturated fatty acids within the oil. Further oxidation causes the oil to become increasingly degraded. Using this low-quality, severely degraded oil for cooking or frying may lead to serious health issues, such as heartburn or nausea.

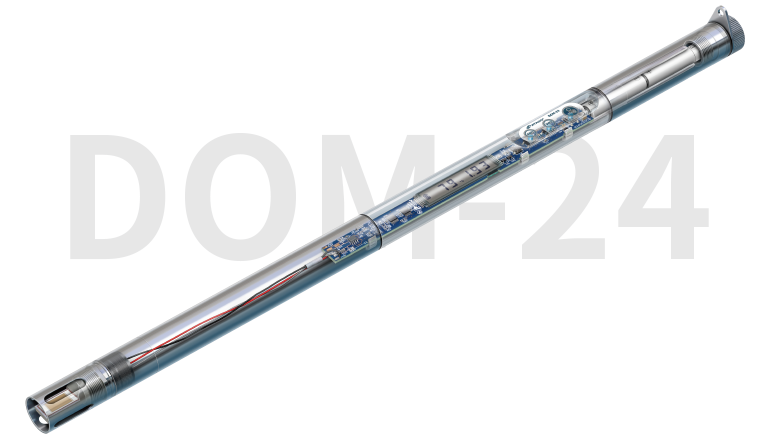

ATAGO recommends using the DOM-24 to periodically check and monitor the quality of your oil in order to maximize its lifespan.

Titration requires troublesome equipment and time consuming preparation. Using third party labs is rather costly. The DOM-24 can easily measure oil degra-dation without any complicated setup. Absolutely no other equi-pment or preparation is needed.

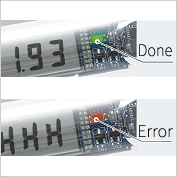

Some methods that utilize test strips or reagent kits result in subjective readings. Moreover, it requires technical knowledge and experience. The DOM-24 provides objective, quantitative values to determine oil degrad-ation. Anyone can obtain preci-se, reliable measurements rega-rdless of skill or experience.

Unlike titration and test strips, which produce refuse,the DOM-24 do not generate any waste or refuse, which means you do not have to worry about disposal. Additionally, unlike reagents, the DOM-24 does not have any sort of "expiration date."

Many people feel uneasy about using potentially dangerous reagents in facilities where food products are produced. The DOM-24 are safe and hygienic which does not utilize any reagents, eliminating the risk of contaminating your food products. The DOM-24 can be completely washed under running water, allowing for thorough hygienic maintenance. With secured distance from the oil to the hand, safety is well considered preventing from burn injuries.

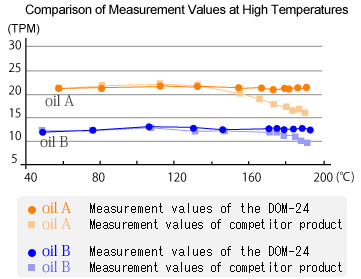

The DOM-24 is equipped with automatic temperature comp-ensation (ATC), making it cap-able of measurements at a wide temperature range of 0˚C to 225˚C. The DOM-24 can provide stable and reliable measureme-nt values, even at high temper-atures.

Measurement history (up to 100 items) can be read by touching a contactless IC card reader / writer connected to a smartph-one or a personal computer.

* The N-Mark is a trademark or registered trademark of NFC Forum, Inc. in the United States and in other countries.

The DOM-24 is the only oil checker that can be used with IH heaters by attaching the sensor cover.

Ishii Food CO.,Ltd.

DOM-24

FIRST BAKING CO., LTD.

DOM-24

TOWER BAKERY

DOM-24

Takasaki University of Health and Welfare

DOM-24

Mogi Tofu Shop

DOM-24

IWAMI FOODS.

DOM-24

Nichirei Foods Inc.

DOM-24

BONZI Foods, Raipur

DOM-24

BIKAJI FOODS INTERNATIONAL LIMITED.

DOM-24

JUBILANT FOODWORKS

DOM-24

Galas nams - Adazi Ltd

DOM-24

KP FOOD SAFETY & HALAL FOOD AUTHORITY

DOM-24

Glico Alimentos Ltda.

DOM-24

Filtrox AG

DOM-24

Valadex Capital Corp

DOM-24

Gopal Snacks

DOM-24

Dah Feng Capsule

DOM-24

PT. MISAJA MITRA PATI

DOM-24

ALL FIELDS

DOM-24

Sadhana Trust

DOM-24

VF&T Co., Ltd.

DOM-24

ARIUM CORPORATION

DOM-24

Determining oil oxidation at home can be done by color or smell, but in professional kitchens and production sites, the methods below are used.

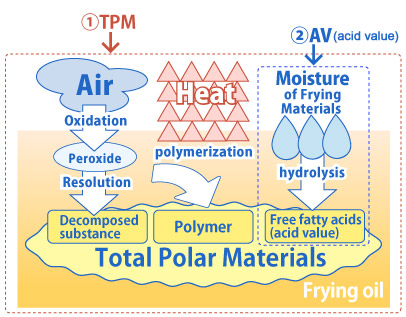

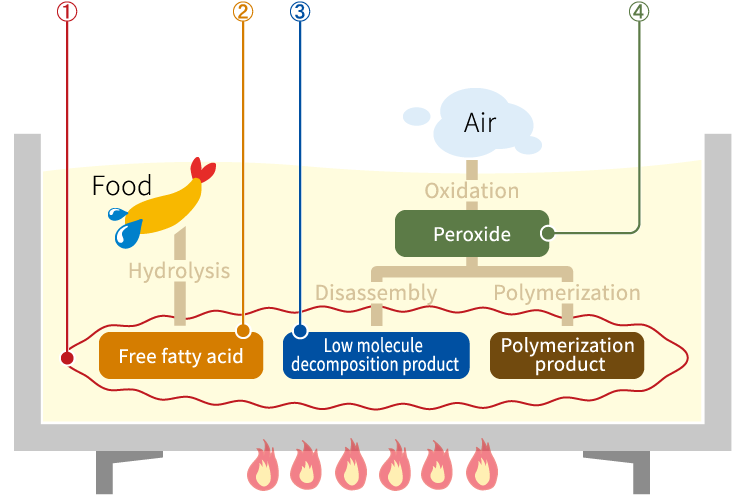

① Total Polar Materials (TPM)

A method used to determine the degradation of frying oil. Total Polar Materials (TPM) refers to all products present in frying oil due to oxidation processes, including free fatty acids, products of low molecular weight decomposition, and polymerized substances. The EU has adopted a value of 25 to 27% as their acceptable upper limit for fats and oils.

② Acid Value (AV)

Acid Value or AV is an index that denotes the amount of free fatty acids caused by hydrolysis. Acid value is a suitable method for evaluating the degree of oxidation for frying oils. Many AV test strips, which can be easily measure the value, are used at food production sites.

③ Carbonyl Value (CV)

It is a measurement denoting the amount of aldehyde and ketone produced in frying oils to determine degradation. Carbonyl compounds can be a good indicator of thermal oxidation. In addition, as the threshold is small, it will impact the smell of fats and oils greatly.

④ Peroxide Value (POV)

Peroxide is generated when oil is exposed to air, causing the unsaturated fatty acids to absorb oxygen. Peroxide value can also be used to measure hydroperoxide but for frying oil the indicator is by decomposition or polymerization.

| Instant noodles | The acid value of fats and oils contained in noodles should not exceed 3 or the peroxide value should not exceed 30. | Standards for Foods, Food Additives | |

|

In fats and oils of noodles dried by oil treatment should be 1.5 or less. The acid value of fats and oils used for oil processing of noodles should be 1.5 or less. |

Japanese Agricultural Standard | ||

|

Confectionery processed with fats and oils (containing 10% or more of fats and oils) |

Selling products that conform to the following (a) and (b). (a) For confectionery products, the acid value of fats and oils contained in their products should not exceed 3, and, the peroxide value should not exceed 30. (b) The confectionery should not exceed an acid value of 5 or more in the fats and oils contained in the product or, the peroxide value should not exceed 50. |

Confectionery Guidelines | |

| Bento box and side dish |

As raw materials: Use those with an acid value of 1 or less (but excluding sesame oil) and a peroxide value of 10 or less. Frying with fats and oils: If the acid value exceeds 2.5, replace with fresh fats and oils. |

Health Code for Lunch Box and Side Dish | |

| Western-style confectionery |

(1) Component specification of raw materials: acid value 3 or less, peroxide value 30 or less (2) Products shall conform to the following standards ①The acid value of fats and oils contained in the product does not exceed 3. ②The peroxide value of fats and oils contained in the product does not exceed 30. |

Healthy Norms of European-style Confectionery | |

| Edible vegetable oils and fats | Oil with low degree of purification | Acid value of 0.20 to 4.0 or less. (Cottonseed, sesame, rapeseed, peanut, olive, palm olein, palm stearin, mixture, flavor oil) | Japanese Agricultural Standard |

| Refined oil | Acid value of 0.20 or less (Olive oil has an acid value of 0.60 or less) | ||

| Salad oil | Having an acid value of 0.15 or less (the one prepared with olive oil has an acid value of 0.40 or less) | ||

Total polar materials (TPM) % is mainly used in Europe as an indicator of cooking oil degradation.

① TPM is a value that expresses the amount of degraded substances (excluding non-polar materials), such as decomposed substances and polymers, calculated primarily from oils and fats (triglycerides).

② In addition to TPM, acid value (AV) is also an indicator used to express cooking oil quality and freshness. It is primarily used in other countries such as Japan and America. AV is a value that expresses the proportionate amount of free fatty acids within oil.

Values will vary depending on the region and sample.

The DOM-24 is capable of switching between both TPM and AV values for measurement.

Please use the scale most suitable to your application.