Digital Viscometer

| JP: | 1344031, 1553531 |

| TW: | D176013 |

| US: |

US D796,362 S, US D922,221S |

| EUIPO: | 002906149-0001 |

| CN: | US D820702S, US D802703S, ZL 2019 3 0711973.X |

| KR: | 30-0917570, 30-0917566, DM/205380 |

| IN: | 003665546-0001, 003665546-0002 |

ONE TOUCH™

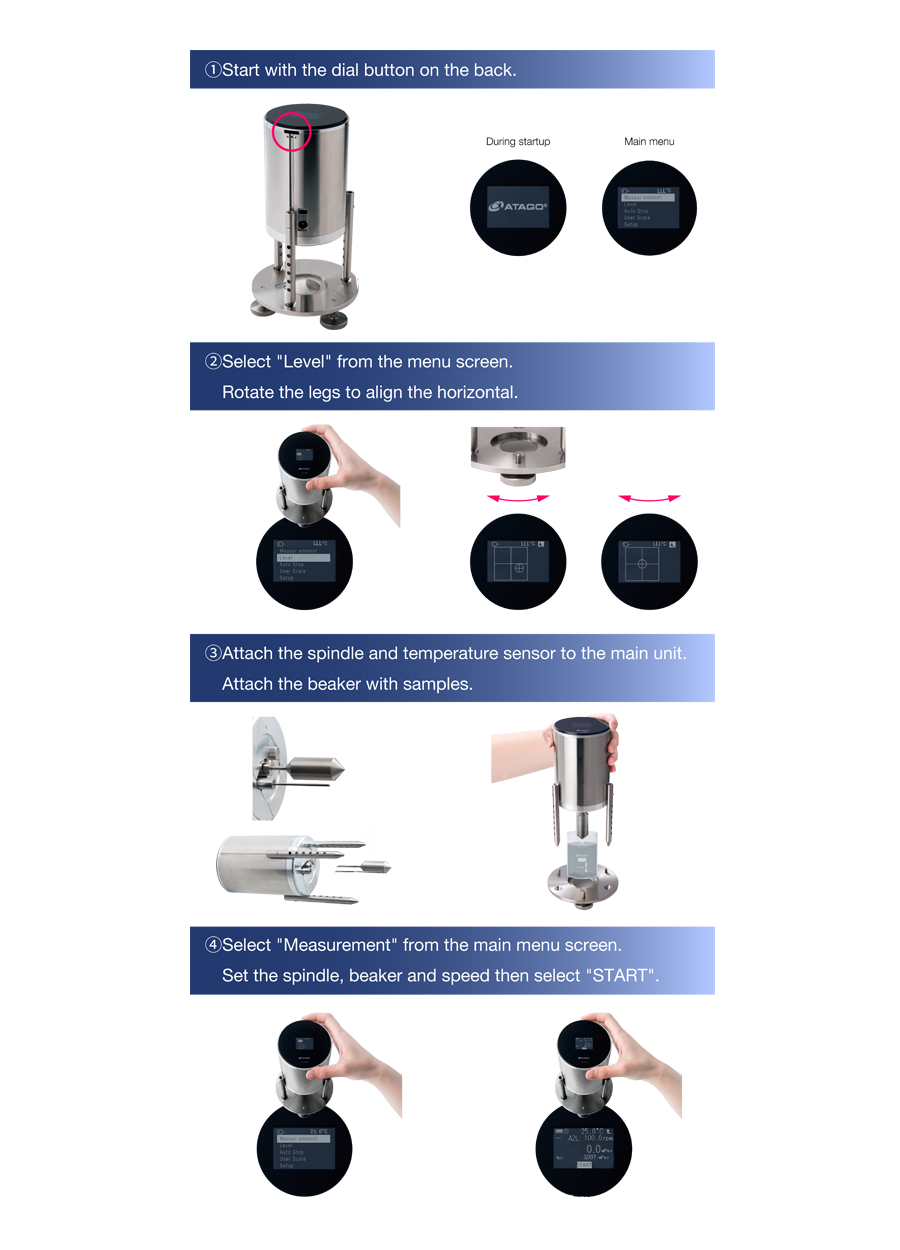

VISCO is very easy to set-up. The spindle can be attached with just ""one touch"" — simply insert the spindle in the instrument.Absolutely no complicated set-up required.

ONE HAND™

Measurement preparation can easily be done with just one hand. Place the beaker underneath the pre-set area and place the instrument on the stand. No troublesome height adjustment necessary.

ONE BUTTON™

Operation requires only one dial button.All operations can be performed with the simple act of ""sliding"" or ""pushing"" the dial button. No more accidental operations due to pushing the wrong button.

The assembly takes 30 seconds. It frees you from the hassle of preparation, cleaning up, and removes hesitation for measurements. Only one button to deal with. From setting up to measurements, you can do it with one hand. The state of the actual assembly is here.

VISCO™ can measure using paper cups or plastic cups. It's disposable and does not require you to wash the beakers. It is safe even in the areas where glassware is restricted.

ATAGO's viscosity meter VISCO™ is very lightweight and compact with a height of 20 cm and a weight of 895 g. Easy to carry from the lab to the production site.

VISCO™ is powered by AC power supplies or batteries. The battery life is about seven hours. Easy measurements, any place and in any situation.

Stress free from loud noise or vibration and environmentally friendly because it does not use refrigerants such as fluorocarbons.

Low viscosity samples can be measured with VISCO™. ATAGO’s VISCO™ has an adapter for low viscosity samples.

The temperature controller is a lightweight, compact and constant temperature device that does not require water circulation.

US:US D922,221S

CN:ZL 2019 3 0711973.X

KR:DM/205380

Since the peltier is used to control the temperature, the sample can be constantly warmed without the use of water. The heavy labor is no longer necessary,no longer a need to worry about algae and mold.

The total weight is about 4 kg and temperature control unit only is merely 2.7 kg. Less than half the weight of a typical constant temperature water bath. The size is just about the size of VISCO™ fitting perfect, without worrying about workspace.

It is operated by two buttons. Despite the common notion that “apparatus and devices used for experiments are considered difficult without being a researcher or expert,” it is an easy to use product that anyone can use.

A novel and stylish design that reverses the image of such conventional viscosity measurement, It can offer not only usability, but also an environment where users can comfortably measure viscosity.

Stress free from loud noise or vibration and environmentally friendly because it does not use refrigerants such as fluorocarbons.

Condiment

Olive oil

Honey and Jam

Liquid Egg

Jelly and agar

Cosmetics

Adhesive

Water glass

Resin, Polymer etc.

Insulator etc.

Glycerin

Lubricant

Slurry

Please feel free to contact us here about other applications.

Ezaki Glico Co., Ltd.

VISCO™ for its portability

Foremost Blue Seal Ltd.

VISCO™ for product development

Tsuru Miso Jyouzou Co., Ltd.

VISCO™ for important maintenance of viscosity

Muginoho Co., Ltd.

VISCO™ for its portability and ease of operation

VISCO™ PackageE

Includes Temp controller

VISCO/VISCO895

VISCO™ PackageA

Includes adapter for disposable containers

VISCO™ PackageB

Includes adapter for low viscosity

Calibration compares the true value and the value measured from the instrument. Calibration is an important task to ensure the reliability of the measurement results. Calibration is recommended when the measurement environment has changed drastically or when the measurement results are out of the norm. If you are considering routine calibration, we recommend that you decide the frequency based on the circumstance in which the instrument is used and past measurement results. ATAGO's viscometer VISCO™ provides the following standard solutions: The standard solutions are available in various viscosity. It is recommended to calibrate with a standard solution that is close to the viscosity of samples being measured.

| Part number | Part name | Contents |

|---|---|---|

| RE-89030 | Viscosity Standard Liquid 2 | 100mL |

| RE-89031 | Viscosity Standard Liquid 5 | 100mL |

| RE-89036 | Viscosity Standard Liquid 200 | 100mL |

| RE-89037 | Viscosity Standard Liquid 500 | 100mL |

| RE-89038 | Viscosity Standard Liquid 1000 | 100mL |

| RE-89039 | Viscosity Standard Liquid 2000 | 100mL |

| RE-89053 | Viscosity Standard Liquid 20 | 500mL |

| RE-89054 | Viscosity Standard Liquid 50 | 500mL |

| RE-89055 | Viscosity Standard Liquid 100 | 500mL |

| RE-89056 | Viscosity Standard Liquid 200 | 500mL |

| RE-89057 | Viscosity Standard Liquid 500 | 500mL |

| RE-89058 | Viscosity Standard Liquid 1000 | 500mL |

| RE-89059 | Viscosity Standard Liquid 2000 | 500mL |

If you would like a standard solution with JCSS calibration certificate, please click here.

| Part number | Part name | Contents |

|---|---|---|

| RE-89010 | Viscosity Standard Liquid JS2.5 | 500mL |

| RE-89011 | Viscosity Standard Liquid JS5 | 500mL |

| RE-89012 | Viscosity Standard Liquid JS10 | 500mL |

| RE-89013 | Viscosity Standard Liquid JS20 | 500mL |

| RE-89014 | Viscosity Standard Liquid JS50 | 500mL |

| RE-89015 | Viscosity Standard Liquid JS100 | 500mL |

| RE-89016 | Viscosity Standard Liquid JS200 | 500mL |

| RE-89017 | Viscosity Standard Liquid JS500 | 500mL |

| RE-89018 | Viscosity Standard Liquid JS1000 | 500mL |

| RE-89019 | Viscosity Standard Liquid JS2000 | 500mL |

| RE-89020 | Viscosity Standard Liquid JS14000 | 500mL |

| RE-89021 | Viscosity Standard Liquid JS52000 | 500mL |

| RE-89022 | Viscosity Standard Liquid JS160000 | 500mL |

Feel free to order or consult from this form Please contact me.

| Part number | Part name |

|---|---|

| 6900 | VISCO™ Temp Controller |

| Part number | Part name |

|---|---|

| RE-79100 | 15mL Beaker |

| RE-79101 | 100mL Beaker |

| RE-76059 | Plastic Cup Adapter |

| RE-79104 | Plastic Cup(100pcs) |

| RE-78141 | Cup Adapter (100pcs of paper cups are included) |

| RE-79102 | Paper Cup (90mL, 100pcs) |

| Part number | Part name |

|---|---|

| RE-77120 | Ultra Low Adapter (ULA) |

| RE-77107 | UL spindle (with hook and hook holder) |

| RE-77121 | Sample cylinder (with cap and o-ring) |

| RE-77117 | UUL spindle 3pcs (with hook and hook holder) |

| Part number | Part name |

|---|---|

| RE-75540 | Temperature sensor |

| Part number | Part name |

|---|---|

| RE-77104 | A1 Spindle |

| RE-77105 | A2 Spindle |

| RE-77106 | A3 Spindle |

| Part number | Part name |

|---|---|

| RE-77114 | A1 Spindle Spindle 5pcs |

| RE-77115 | A2 Spindle Spindle 5pcs |

| RE-77116 | A3 Spindle Spindle 5pcsdle 5pcs |

| RE-77100 | Set of spindles (A1,A2,A3) |

※Having multiple spindles can eliminate washing after each used for improved efficiency.

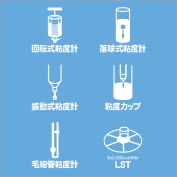

There are different types viscometers that uses various measurement methods.

There are different types viscometers that uses various measurement methods.

For example, in the Japanese Industrial Standard JIS Z 8803, viscometers are classified as follow:

• Capillary viscometers

• Falling ball viscometers

• Rotational viscometers

• Vibrational viscometers

There are also other measurement methods such as viscosity cups and Line Spread Tests (LST).

ATAGO's viscosity meter VISCO™ is measured on a principle called rotational viscosity.

Rotational viscometer is one of the most common viscometers used. The structure is simple, easy to use, and the measurement range is wide and can be measured with high accuracy. When a cylindrical spindle is placed in the sample and rotated at a constant speed, the viscosity is determined by measuring the torque (shear stress) acting on the cylindrical surface. There are different types of spindles: coaxial double cylinder, single cylindrical, and cone and plate. The cone plate type can determine the flow characteristics of non-Newtonian fluids by changing the rotational speed.

Rotational viscometer is one of the most common viscometers used. The structure is simple, easy to use, and the measurement range is wide and can be measured with high accuracy. When a cylindrical spindle is placed in the sample and rotated at a constant speed, the viscosity is determined by measuring the torque (shear stress) acting on the cylindrical surface. There are different types of spindles: coaxial double cylinder, single cylindrical, and cone and plate. The cone plate type can determine the flow characteristics of non-Newtonian fluids by changing the rotational speed.

Q I'm considering purchasing, can I try it before I buy it?

A

Free trial is available.

Q How do I choose right spindle and speed?

A Standard VISCO™ comes with three types of spindles. Please contact our sales department for the selection criteria. Guidelines for each type of beaker size, speed, and spindle are also available in the instruction manual. Note that the torque should be between 10 and 100% because load less than 10% will not have enough load on the spring.

Q When the speed or the beaker size is changed, a different viscosity is measured. Is it measuring correctly?

A When the rotational speed and the beaker size change, the viscosity also changes. This is because viscosity is affected by measurement conditions. When measuring a sample, make the measurement conditions consistent.

Q Can VISCO™ be calibrated?

A VISCO™ can be calibrated using a standard solution. For the value of the standard solution, please refer to the measured value in the instruction manual.

Q Is there a correlation with the B-type viscometer?

A Some samples do and others don't have correlation. Check to see the correlation with the free trial unit. If there is correlation, you can use the user scale feature to set the same value to be displayed.

Q Can I adjust the temperature?

A Temp controller can be used. When using a waterbath, be careful not let the water in the sample. Also, if you are measuring a high temperature sample, set the wait time and create a temperature compensation table for the measurement sample. For more information, please contact our sales department.

Q Is it possible to output data?

A Data can be output using the AUSB-Mini-B cable.