Measuring viscosity with VISCO™ changed viscosity management from sensory to a numerical value and made the viscosity of soup more consistent and stabilized the mouth feel.

VISCO™ is lightweight, compact and easy to carry, so it can be carried to the manufacturing site for quick measurement. Because it is easy to operate and does not require any special skill, it enables smooth manufacturing.

Ezaki Glico measures the viscosity of yogurt and pudding. They purchased the VISCO™ (Package B) for its portability, which makes it possible to use in the factory. The VISCO™ received high praise at Eizaki Glico for its compact and stylish design with accurate and stable measurements.

At Foremost Blue Seal Ltd. the VISCO™ is used to manage the viscosity of their ice cream mix. For ice cream, the way it melts in your mouth is directly related to how good it tastes. The VISCO™ is mainly used during product development and it prevents equipment failure during the filling process. The VISCO™ was highly evaluated because only a small amount of test sample is required for testing and virtually anyone, even first-time users, can easily operate the VISCO™.

Tsuru Miso Jyouzou Co., Ltd. was founded during the Meiji period (1871) and is located in Yanagawa City of the Fukuoka Prefecture. Having a history of over 140 years, their motto is to follow tradition, and keep up the same formula and taste. They also make ‘miso’ (paste made from fermented soybeans) used in miso dispensers for the restaurant industry. If the amount of ’miso’ dispensed is not consistent, the flavor changes. One of the key factors in measuring a consistent amount is viscosity. In addition, if the ’miso’ is too thick, it can clog the dispenser. For this reason maintaining the viscosity of the ’miso’ is also important. Tsuru Miso Jyouzou Co., Ltd. is fond of the fact that the VISCO™ is very easy to use on their production floor. The VISCO™ only requires a small amount of test sample in order to get a measurement. Tsuru Miso Jyouzou Co., Ltd. was happy that their miso would not go to waste.

Muginoho Co., Ltd. operates a franchise of cream puff specialty stores called “Beard Papa’s Fresh and Natural Cream Puffs.” In order to keep the cream puffs at a consistent firmness, the viscosity of the dough is measured. In the pursuit of the perfect crunchiness at first bite, and the smooth, creamy, taste, Beard Papa’s is very particular about their ingredients and preparation methods. To deliver the same fresh, light, creamy, and flaky consistency every time Beard Papa’s chose the VISCO™ for its onsite “portability” and “ease of operation” for anyone.

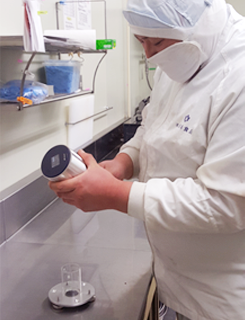

Getting the VISCO™ ready for use

Katori Foods has been producing specialty handmade quality frozen foods for over thirty years. All food is handmade so Katori Foods is consequently able to customize their products based on the customer’s tastes, size or ingredient ratio and other detailed requests, tailoring to small order lots. Katori Foods uses these strengths to manufacture food that does not seem like frozen food, but that of a home cooked meal, similar to ready made foods found at the store, are Katori Foods major product.

Katori Foods focuses on monitoring the frying batter when making fried foods such as ‘rolled katsu’ (fried pork rolls) or ‘tatsuta age’ (fried chicken) and so on. If the batter is too thick, the breading will be too thick when fried, leading to customer complaints. If the batter is too runny, the beading will not adequately cover the food resulting in lack of flavor. When deep frying food, monitoring the viscosity of the frying batter liquid is one of the most important control points.

In order to monitor the viscosity of liquid batter, normally a viscometer would be needed. Below are the reasons why a normal viscometer would not work.

ATAGO's VISCO™ solve dall aforementioned problems.

When measuring the viscosity of the batter, it needs to be measured quickly, and near the production site, as difference in temperature can affect measurement results. Traditional viscometers were too large and could not be used in the production area, but ATAGO's handy sized VISCO™ is compact and can be used on the production site. The VISCO™ also can be battery operated so it can be used virtually anywhere.

Easy operation of the VISCO™ was one of the reasons for choosing VISCO™. To operate the VISCO™, only one button is needed so there is no confusion when taking measurements. There are people of many different ages and genders that work on the production floor. Also depending on the shift, not always the same person will be taking measurements. An instrument that anyone can easily take measurements, was a prerequisite for implementing the VISCO™.

Speaking with Katori Foods, what stood out was how much importance they place on “fostering workforce education.” Katori Foods particularly focuses on “handmade” food; as the name suggests, food is made by “a human being”. Food made by a person’s hand is then eaten by consumers. That is especially why Katori Foods strongly believes in improving quality and consistency with the ultimate result being improved sanitation management and quality control. Also by adding a numerical values to what was once only determined by the senses, is a short cut to workforce education and the VISCO™ is of great use in achieving this. Consistency in quality control is not the only achievement brought by VISCO™. Building an environment where anyone can work is where the VISCO™ truly succeeded.

Thank you for taking the time to speak with me and sharing such valuable information. (Katori Foods also take small lot orders by customer request and can customize foods depending on the tastes of individual customers.)

At Joint Enterprise Cooperative Worker’s Collective

Joint Enterprise Cooperative Worker’s Collective Bon manufactures jam and syrup using all natural ingredients.

Without using chemical seasoning, artificial colors, artificial flavoring or preservatives, Joint Enterprise Cooperative Worker’s Collective Bon, offers products utilizing seasonal local produce and fruits, bringing the best out of the ingredients.

As part of the quality control procedures, at Joint Enterprise Cooperative Worker’s Collective Bon, ATAGO’s viscosity meter and Brix meters are used. Both the viscosity and Brix meters are used during inspections before filling the bottles.

Mr. Kobayashi who is in charge of manufacturing mentioned as follows:

QHow useful is the VISCO™ ?

AVISCO™ is used to test the viscosity of our blueberry sauce. Originally, we were not using a viscosity meter but we decided to implement in order to make higher quality products. The blueberry sauce is generally used as a spread on bread or as a sauce for yogurt. Maintaining the right texture and viscosity was just as important as the flavor.

Compared to a B type viscosity meter, the VISCO™ is low cost and simple to operate, that anyone can easily use the VISCO™ at the production site. By using the VISCO™, we are able to screen and catch defective sauces that are too low in viscosity prior to shipment.

QHow user friendly is digital Brix Meter PR-201α?

AThe use of the PR-201α is as simple as placing the test sample on the prism and pressing a button. It is convenient and easy to operate. Even with highly dense and viscous samples like jams or fruits sauces PR-201α provides steady measurements. The condition of products can be checked by using the human senses but by actually taking measurements and providing numerical backing, it can prove the products’ viability and reassures the manufacture.

Thank you for taking the time out of your busy schedule to speak with us today Mr. Kobayashi.

Products from Joint Enterprise Cooperative Worker’s Collective Bon are available for purchase online.

If interested, please see their website.

We thank you for your continuing patronage.

Neo Tech specializes in metal cutting work and surface treatments for automotive metal parts as well as mold fabrication and high-grade coatings for medical related equipment. When measuring viscosity of the coating materials, flow cup viscometer was used, however, in order to measure with more accuracy, Neo Tech decided to purchase the VISCO™.

At Neo Tech, equipment and condition requirements for coating are determined by each product. For example, coating material for medical equipment is low in viscosity and the way coating is applied is changed according to its viscosity.

At Neo Tech, the manufacturing plant for the medical equipment and the factory for automotive parts are in a different location.

Also,the painting area is separately located which made VISCO's portability to be highly rated by Neo Tech. The VISCO™ was a perfect match to meet the selection criteria of Neo Tech.It expresses viscosity in numerical form, has an easy measurement method, stable measurement accuracy, and on-site portability.

Thank you for your continuing patronage.

Neo Tech web site

https://www.neotec.ne.jp/company

Horitech Co., Ltd.

Horitech Co., Ltd.

OEM cosmetic products

Horitech is a company that manufactures small batch OEM cosmetic products such as shampoos and facial lotions. The quality of the product is assessed using VISCO™ to test how easily products come out of a container and how well it spreads on hands. The shampoos made by Horitech are popular with many repeat customers that purchase their products looking for “the same texture” which makes viscosity measurement indispensable. Horitech had been using type B viscometer that required sample volume of 500mL. To avoid cumbersome cleaning and reduce cost,Horitech decided to purchase VISCO™,which can measure viscosity with mere sample volume of 15mL.

Horitech Co., Ltd.'s website

https://horitec-oem.net/

Demlite Co., Ltd.

Demlite manages the viscosity of cosmetics and cleaning products during manufacturing process to check the rate of swelling of raw materials. For cosmetic and cleaning agents, the material viscosity increases during the manufacturing process. Each product has different optimal viscosity which makes it all the more important to know the right timing. Once a material hardens, the process becomes irreversible. To achieve the maximum production yield, the ability to measure viscosity as the products are manufactured is prerogative.Demlite chooses to use VISCO™ and embrace its portability, user friendliness and ease of taking measurement on-site.

Demlite Co., Ltd.'s website

http://www.demlite.co.jp/