In-line Concentration Monitor

Simple, easy IoT automation with the inline concentrarion monitor CM-BASEα! Automating measurement contributes to the prevention of human error, saves on labor, and reduces manpower! Avoid doing major installation by using a hose connector or metal pipeline fitting.

It has been selected as a "Smart Manufacturing Support Tool" as an IoT tool that can be used easily and at low cost by the Robot Revolution Initiative Council (RRI) supported by the Ministry of Economy, Trade and Industry. We are proud of the No. 1 track record in the metal processing industry for water-soluble cutting oils, grinding fluids, cleaning fluids, etc.

From the CM-BASEα series, highend CM-BASEα-Plus with an expanded measurement and temperature range is now available! During the world push for factory automation, this is the perfect model to take a step towards automation at a price range that is attainable for both small and medium sized food companies.

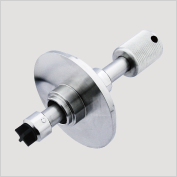

Easily held in the palm of your hand, it is a model that has the display on the front, and the sensor on the back.

Special scales are available for many different samples, such as Salt solution concentration (W / W), salt solution specific gravity, salt solution bome degree, seawater concentration (‰), seawater specific gravity, seawater bome degree, soymilk concentration, citric acid concentration (W / W), DMF concentration (W / W) , Hydrogen peroxide concentration (W / W), sodium hydroxide concentration (W / W), magnesium chloride concentration (W / W), urea water concentration, cutting oil concentration, dampening water concentration, and more!

The prism wiper is an available accessory to be used for those samples where sample buildup is unavoidable. There is no need to stop production or remove the in-line refractometer multiple times to clean the prism surface. The prism wiper is installed directly opposite of the sensor and manually wipes off the deposits on the prism surface.

For data output,recorder output (DC4mA to 20mA) and RS-232C output are available. Detecting changes in concentration in real time contributes to immediate quality issue reaction and response, prevention of human error, and quick cause investigation by analyzing saved measurement data, all of which point to strong, reliable quality control process.

ATAGO's inline refractometer meets the safety and health standard institutions EHEDG and 3-A Sanitary Standards requirement for instrumentation's wetted parts surface finish to be Ra 0.8 or less, clearing EC No 1935/2004 as well as FDA (21 CFR)-GRAS(Generally Recognized as Safe). These specifications clear the component requirements for stainless steel so the inline refractometer can be used with confidence.

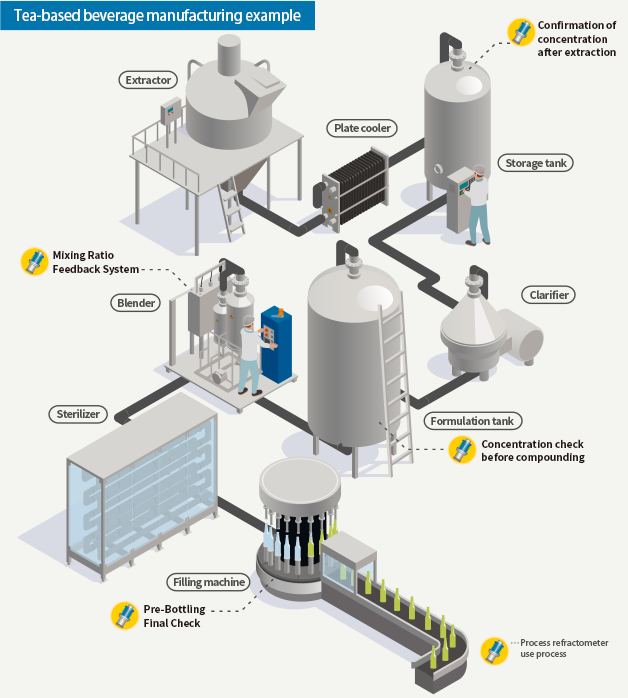

Block nonconformities by process

Check the concentration of the extract

Manage extraction yield by measuring the Brix of the extracted solution.Depending on the extraction rate, re-extraction may be performed.

Mixing Ratio Feedback System

The mixing ratio can be detected in real time, and feedback is given so that there are no non-standard products.

Pre-Bottling Final Check

A final check on the product before bottling is made to make sure it is within specifcations.It can also be used to reduce liquid loss by controlling the switching to water during cleaning.

For details, please contact ATAGO.

SUS(standard specification)

Stainless steel with high strength and excellent corrosion resistance.Sanitary specification.

Titanium

Metal with high strength, light weight, corrosion resistance, heat resistance. In particular, it has higher corrosion resistance to salt than the stainless steel.

Hastelloy

Alloy with high corrosion resistance and heat resistance. Alloy with high corrosion resistance and heat resistance. * Hastelloy is a trademark of Haines Corporation, USA.

For details, please contact ATAGO.

What is VARIVENT®?

VARIVENT® is a standard for pipeline installation. Mainly used in Europe, but also in countries around the world. The wetted parts of In-line Refractometers may be customized to work with VARIVENT® components. PRM series and CM series fittings that meet VARIVENT standards are also available.

* VARIVENT® is a registered trademark of GEA Tuchenhagen.

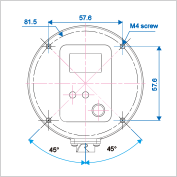

Pipeline Fitting Sizes

Correct Installation Methods

Choose Pipeline Fitting Type and Size